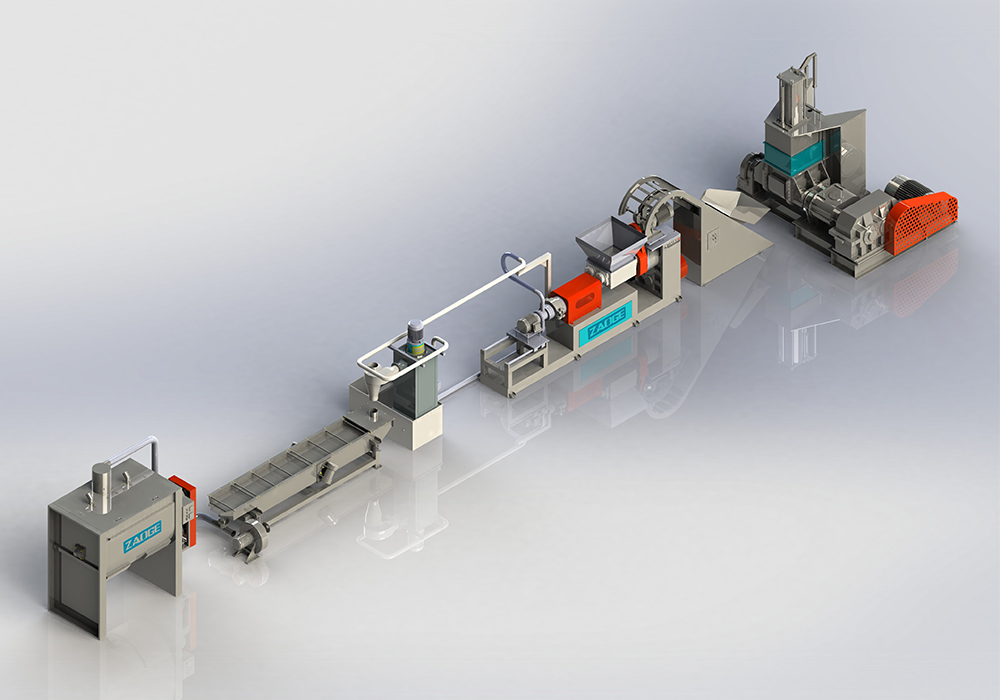

Ob lub dab teg Yas Granulator

Kev piav qhia

Cov khoom siv no yog tsim rau granulating EVA, TPR, roj hmab PP, HDPE, LDPE, LLDPE, HIPS, PS, ABS, PC, PMMA, TPU, EVA thiab lwm yam khoom siv rov ua dua tshiab. Nws txais German reducer lub cev muaj zog thiab siab torque iav lub thawv, uas zoo txuag hluav taws xob mus txog 20%; Kev tswj qhov kub thiab txias yog qhov tseeb, kev pub mis ceev yog qhov sib xws, thiab qhov ceev yog qhov yooj yim heev los kho; cov ntsia hlau thiab lub thoob yog ua los ntawm cov khoom siv txawv teb chaws thiab kho tshwj xeeb, uas muaj kev hnav zoo thiab ua haujlwm ntev; nws txais yuav tsis nres ob chav kem hydraulic hloov pauv, uas yog yooj yim thiab yooj yim rau kev khiav lag luam, thiab yog qhov tsim nyog rau kev txhim kho kev ua haujlwm thiab kev tsim khoom.

Kev piav qhia

Cov khoom siv no yog tsim rau granulating EVA, TPR, roj hmab PP, HDPE, LDPE, LLDPE, HIPS, PS, ABS, PC, PMMA, TPU, EVA thiab lwm yam khoom siv rov ua dua tshiab. Nws txais German reducer lub cev muaj zog thiab siab torque iav lub thawv, uas zoo txuag hluav taws xob mus txog 20%; Kev tswj qhov kub thiab txias yog qhov tseeb, kev pub mis ceev yog qhov sib xws, thiab qhov ceev yog qhov yooj yim heev los kho; cov ntsia hlau thiab lub thoob yog ua los ntawm cov khoom siv txawv teb chaws thiab kho tshwj xeeb, uas muaj kev hnav zoo thiab ua haujlwm ntev; nws txais yuav tsis nres ob chav kem hydraulic hloov pauv, uas yog yooj yim thiab yooj yim rau kev khiav lag luam, thiab yog qhov tsim nyog rau kev txhim kho kev ua haujlwm thiab kev tsim khoom.

Paub meej ntxiv

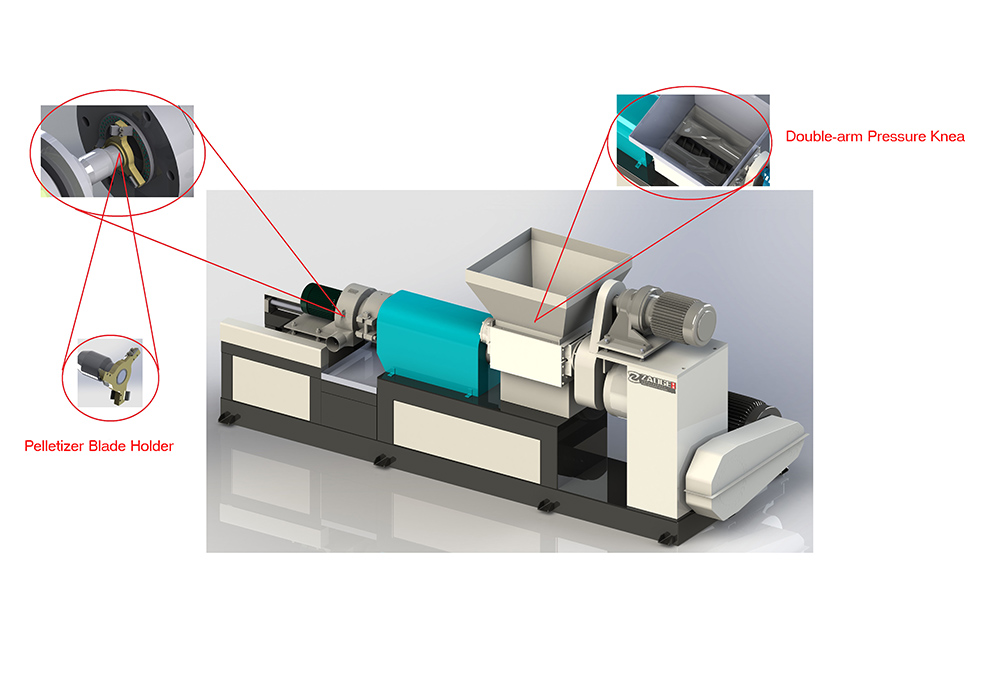

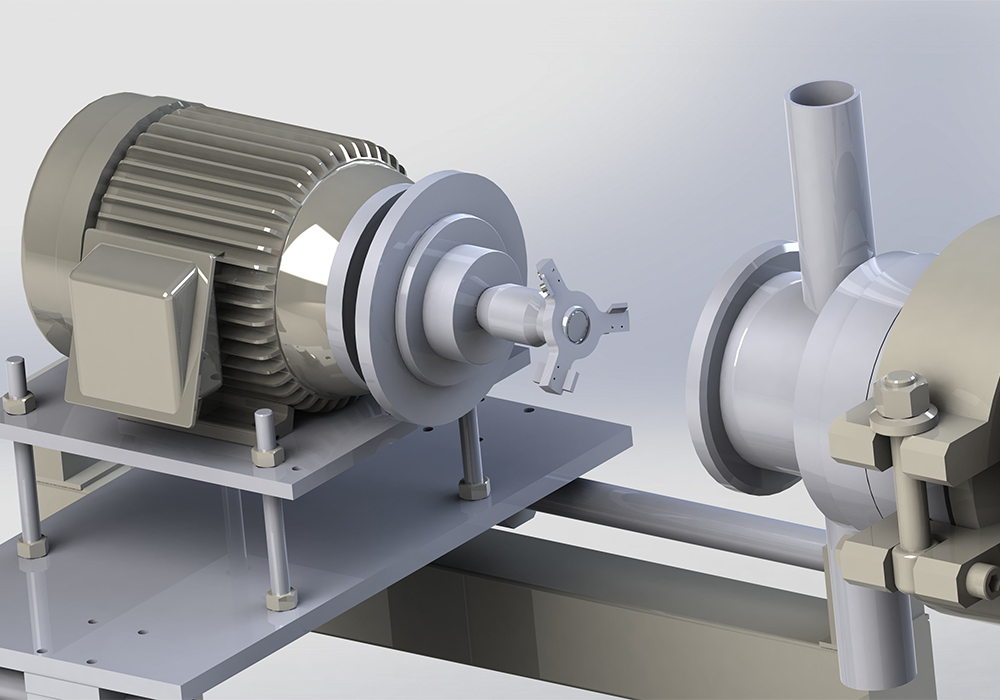

Tuag taub hau txiav

Cov khoom siv yog thauj los ntawm cov ntsia hlau mus rau lub taub hau tuag rau kev txiav tam sim, ua rau cov hmoov tsawg dua thiab muaj peev xwm tswj tau qhov loj thiab cov duab ntawm cov khoom, txhim kho kev ua haujlwm zoo thiab raug.

Ob chav-Arm Discharge

Nrog ob sab caj npab qauv, nws nyob hauv qhov chaw me me, nws tuaj yeem kho qhov nrawm raws li cov ntaub ntawv sib txawv thiab cov txheej txheem, kom cov ntaub ntawv sib xyaw nrog kev sib hloov ceev thiab ua rau hmoov, uas tsis tsuas yog txhim kho kev tsim khoom, tab sis kuj ua tiav cov txiaj ntsig zoo tshaj plaws.

Ob chav-Arm Discharge

Nrog ob sab caj npab qauv, nws nyob hauv qhov chaw me me, nws tuaj yeem kho qhov nrawm raws li cov ntaub ntawv sib txawv thiab cov txheej txheem, kom cov ntaub ntawv sib xyaw nrog kev sib hloov ceev thiab ua rau hmoov, uas tsis tsuas yog txhim kho kev tsim khoom, tab sis kuj ua tiav cov txiaj ntsig zoo tshaj plaws.

Ntsia Hlau Thiab Txiv Ntoo

ib tug high-precision machining txheej txheem uas txhim khu lawv cov load-bearing muaj peev xwm, hnav tsis kam, thiab stability thaum lub sij hawm ua hauj lwm, yuav txo tau cov kev vibration thiab suab nrov thiab xyuas kom meej cov kis tau tus mob cov kev taw qhia thiab stability.

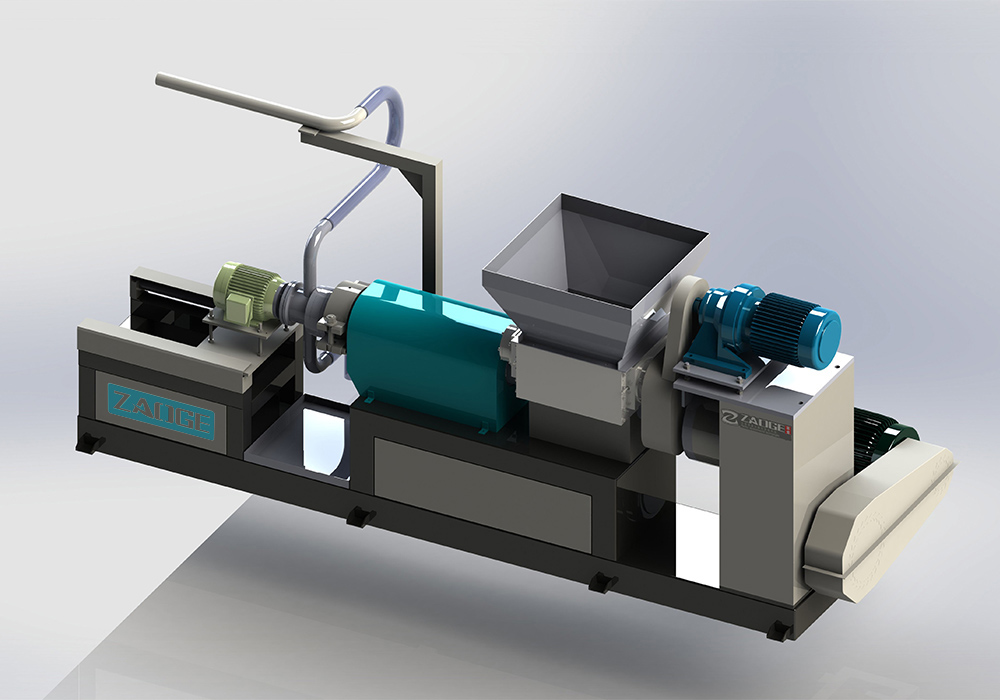

Internal tov khoom

Siv lub tshuab kaw, lub tshuab no sib xyaw cov khoom sib txawv ntawm kev kub ceev hauv qhov sib tov sib xyaw. Qhov no ua rau muaj kev siv hluav taws xob tsawg thiab nrawm, sib xyaw ua haujlwm zoo.

Internal tov khoom

Siv lub tshuab kaw, lub tshuab no sib xyaw cov khoom sib txawv ntawm kev kub ceev hauv qhov sib tov sib xyaw. Qhov no ua rau muaj kev siv hluav taws xob tsawg thiab nrawm, sib xyaw ua haujlwm zoo.

Daim ntawv thov Granulator

Cov khoom siv roj hmab

EVA cov khoom

Cov khoom siv PVC

Cov khoom siv PMMA

ABS khoom

PS khoom

Specifications

| ZGDG series | |||||||

| Hom | ZWM-85 (MATCH 20L) | ZGDG-100 (MATCH 35L) | ZGDG-120 (MATCH 55L) | ZGDG-150 (MATCH 75L) | ZGDG-165 (MATCH 110L) | ZGDG-180 (MATCH 150L) | |

| Main Screw Diameter | f85mm ua | φ100 hli | f 120 mm | f150mm ua | f165mm ua | f180mm ua | |

| Ntsia hlau ntev(L/D) | 10:1 | 10:1 | 10:1 | 10:1 | 10:1 | 10:1 | |

| Tsav Tsav | 25 hp cas | 30HP ib | 40 hp cas | 50HP ib | 60 hp cas | 60 hp cas | |

| Productivity | 100 ~ 150kg / h | 200-300kg / h | 300-400kg / h | 400-600kg / h | 600-750kg / h | 750-1000kg / h | |

| Kneader Force pub zog | 5HP ib | 7.5hp ib | 7.5hp ib | 10HP ib | 10HP ib | 10HP ib | |

| Rotate Ceev | 35 r.pm ib | 35 r.pm ib | 35 r.pm ib | 35 r.pm ib | 35 r.pm ib | 35 r.pm ib | |

| Kev Tswj Kub Kub | 3 ZONES | 3 ZONES | 4 ZONES | 4 ZONES | 4 ZONES | 4 ZONES | |

| Barrel Cooling Device | Kiv cua txias

| ||||||

| Tso tawm Txoj kab uas hla | 3 ~ 5 hli | 3 ~ 5 hli | 3 ~ 5 hli | 3 ~ 5 hli | 3 ~ 5 hli | 3 ~ 5 hli | |

| Granulating Tsav | 2HP ib | 2HP ib | 3HP ib | 3HP ib | 3HP ib | 3HP ib | |

| Cov Cuab Yeej Cuab Yeej | Kiv cua txias lossis dej txias | ||||||

| Iav Box | OIL BATH LUBRICATION | ||||||

| Ceev Variation | VIM LI CAS | ||||||

| Blower lub cev muaj zog | 3 npx 4 | 3 npx 4 | 3 npx 4 | 5hpx 5 | 5hpx 5 | 7.5 hpx 5 | |

| Txias Barrel | 2 ~ 4 TSI | ||||||

| Cia Barrel Capacity | 200 kgs | 600 kgs | 600 kgs | 1000 kgs | 1000 kgs | 1000 kgs | |

| Qhov ntev(L*W*H)mm | 3100x1650x1600 | 3350x1850x1950 | 3800x1800x1950 | 4450x1950x2050 | 4800x1950x2050 | 4800x1950x2050 | |

| Qhov hnyav | 2000 kgs | 2500 kgs | 3000 kgs | 3500kgs ib | 4000 kgs | 2000 kgs | |