1. Kev txhaj tshuaj molding txoj cai

Ntxivgranular los yog hmoov yasmus rau lub hopper ntawm lub tshuab txhaj tshuaj, qhov twg cov yas yog rhuab thiab yaj kom tswj tau lub xeev ntws. Tom qab ntawd, nyob rau hauv ib lub siab, nws yog txhaj rau hauv ib lub pwm kaw. Tom qab txias thiab shaping, lub melted yas solidifies mus rau hauv lub xav tau ib feem.

2. Cov yam ntxwv ntawm kev txhaj tshuaj molding

Lub voj voog ntawm kev txhaj tshuaj molding yog luv luv thiab cov khoom tsim tau siab. Siv kev txhaj tshuaj molding tuaj yeem tsim cov khoom yas nrog cov duab nyuaj, qhov xav tau loj, thiab ntau yam ntxig, uas yog qhov nyuaj rau kev ua tiav los ntawm lwm txoj kev yas molding; Qhov thib ob, kev txhaj tshuaj molding yog ib qho yooj yim kom ua tiav automation hauv cov txheej txheem ntau lawm, xws li txhaj tshuaj, demolding, rooj txiav, thiab lwm yam txheej txheem ua haujlwm. Yog li ntawd, kev txhaj tshuaj molding tau siv dav.

2.1 Qhov zoo:

Lub voj voog luv molding, kev ua haujlwm siab ntau lawm, yooj yim rau kev ua tiav automation, muaj peev xwm tsim cov khoom yas nrog cov duab nyuaj, qhov ntev, cov hlau los yog cov hlau tsis zoo, cov khoom ruaj khov, thiab dav adaptability.

2.2 Disadvantages:

Tus nqi ntawm cov khoom siv txhaj tshuaj molding yog qhov siab; Cov qauv ntawm kev txhaj tshuaj pwm yog complex; Cov nqi tsim khoom siab, lub voj voog ntau lawm ntev, thiab tsis tsim nyog rau kev tsim cov khoom yas ib leeg thiab me me.

3. Daim ntawv thov

Tsuas yog ob peb cov ntaub ntawv thermoplastic (fluoroplastics), yuav luag txhua cov ntaub ntawv thermoplastic tuaj yeem tsim tau siv txoj kev txhaj tshuaj molding. Txhaj tshuaj molding tsis yog tsuas yog siv rau molding ntawm cov ntaub ntawv thermoplastic, tab sis kuj tau ua tiav siv rau molding ntawm thermosetting plastics.

Tam sim no, nws cov khoom molded account rau 20-30% ntawm tag nrho cov khoom yas. Txhawm rau nthuav dav ntxiv ntawm kev txhaj tshuaj molded yas qhov chaw, qee qhov kev txhaj tshuaj tshwj xeeb tau tsim los rau molding yas qhov chaw nrog kev ua haujlwm tshwj xeeb lossis cov qauv tsim, xws li kev txhaj tshuaj ntawm cov khoom yas siab, ntau xim txhaj tshuaj ntawm cov khoom sib xyaw xim, cov xuab zeb txhaj tshuaj ntawm cov khoom siv sib txawv sab hauv thiab sab nraud, thiab kev txhaj tshuaj molding ntawm optical pob tshab yas qhov chaw.

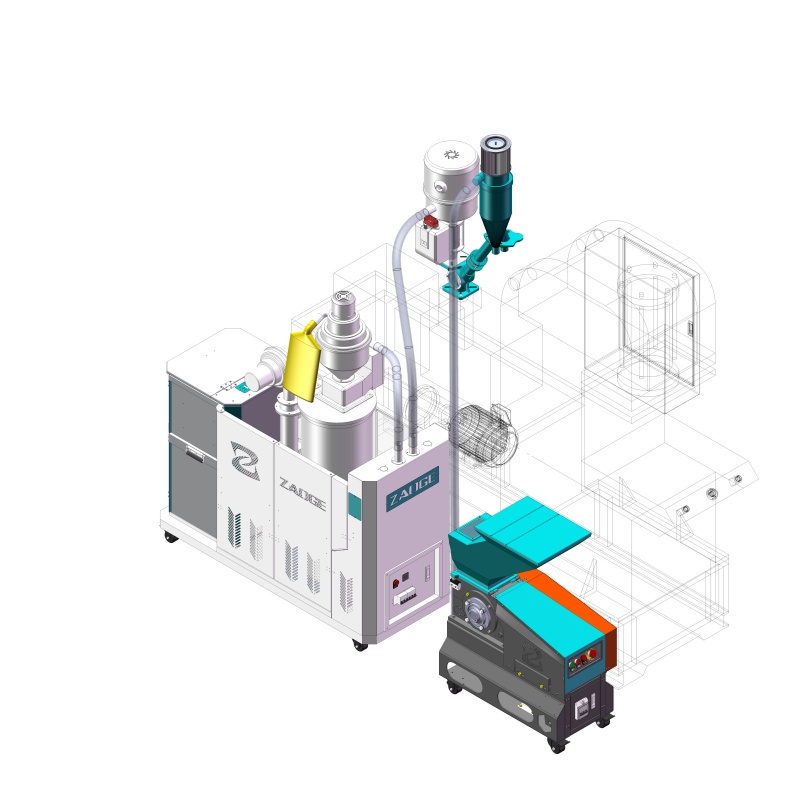

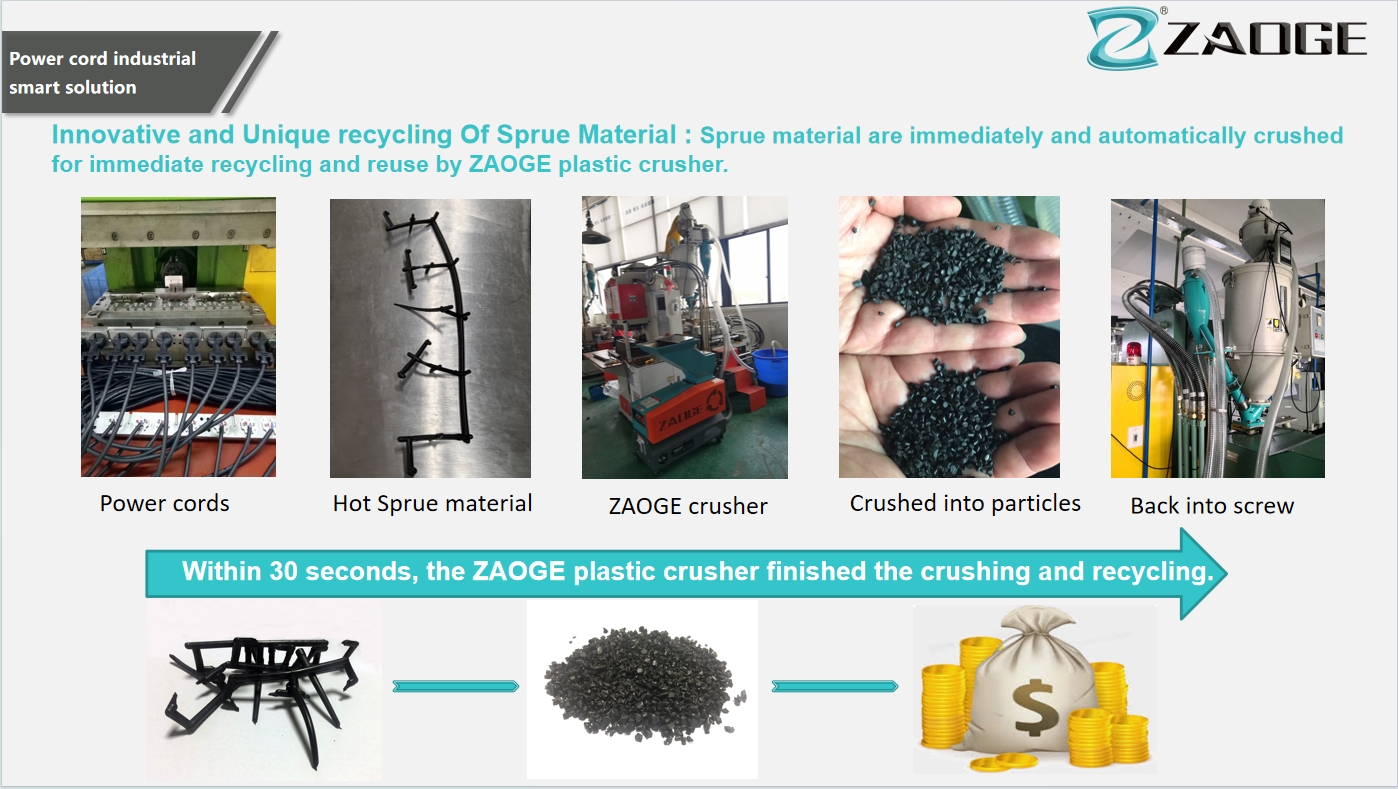

ZAOGE Automated Thermal Crushing Ib puag ncig tiv thaiv kev siv tshuajTshwj xeeb rau cov yas mos

ZAOGE Plastic CRUSHERhaum rau cov teb ntawm cov ntaub ntawv cables, ntsaws cables, cable cables, lub zog tshiab, thiab hloov tau cov khoom molding (xws li PVC, PP, PE, TPE, TPU, thiab lwm yam mos yas yas.

Post lub sij hawm: May-13-2024