(1) Kev xaiv khoom siv tsis raug.Thaum xaiv cov cuab yeej, qhov siab tshaj plaws txhaj tshuaj ntim ntawm lub tshuab txhaj tshuaj molding yuav tsum ntau dua li qhov hnyav tag nrho ntawm cov yas thiab lub nozzle, thiab tag nrho qhov hnyav txhaj tshuaj tsis tuaj yeem tshaj 85% ntawm cov yas ntim ntawm lub tshuab txhaj tshuaj molding.

(2) Pub tsis txaus.Txoj kev siv feem ntau los tswj kev pub noj yog txoj kev ntim ntim ruaj khov. Cov menyuam pub ntim thiab qhov loj me ntawm cov khoom siv raw yog ib yam, thiab seb puas muaj qhov tshwm sim "choj" nyob rau hauv qab ntawm qhov chaw noj mov. Yog tias qhov kub ntawm qhov chaw nres nkoj pub yog siab dhau, nws tseem yuav ua rau cov khoom tsis zoo poob. Hauv qhov no, qhov chaw nres nkoj pub yuav tsum tau muab tshem tawm thiab txias.

(3) Cov khoom tsis zoo fluidity.Thaum cov khoom siv raw fluidity tsis zoo, cov yam ntxwv ntawm cov pwm yog qhov laj thawj tseem ceeb rau kev txhaj tshuaj tsis txaus. Yog li ntawd, qhov stagnation defects ntawm pwm casting system yuav tsum tau txhim kho, xws li tsim nyog qhov chaw khiav hauj lwm, nthuav lub rooj vag, khiav thiab txhaj tshuaj qhov chaw nres nkoj loj, thiab siv lub nozzle loj. Nyob rau tib lub sijhawm, tus nqi tsim nyog ntawm cov khoom ntxiv tuaj yeem muab ntxiv rau cov khoom siv raw los txhim kho cov khoom ntws ntawm cov resin. Tsis tas li ntawd, nws tseem yuav tsum tau xyuas seb cov khoom siv rov ua dua tshiab hauv cov khoom siv raw yog ntau dhau thiab tsim nyog txo nws cov nyiaj.

(4) Cov roj nplua nyeem ntau dhau.Yog hais tias tus nqi ntawm cov roj nplua nyeem nyob rau hauv cov ntaub ntawv raw yog ntau dhau, thiab qhov sib txawv ntawm qhov kev txhaj tshuaj ntsia hlau lub nplhaib thiab lub thoob yog loj, cov khoom molten yuav ntws rov qab hnyav rau hauv lub thoob, ua rau tsis txaus noj thiab ua rau muaj kev txhaj tshuaj. Hauv qhov no, cov roj nplua nyeem yuav tsum raug txo, qhov sib txawv ntawm lub thoob thiab cov ntsia hlau txhaj tshuaj thiab lub nplhaib kos yuav tsum raug kho, thiab cov khoom siv yuav tsum tau kho.

(5) Cov khoom txias impurities thaiv cov khoom siv channel.Thaum impurities nyob rau hauv cov khoom molten thaiv lub nozzle los yog cov khoom txias thaiv lub rooj vag thiab khiav, lub nozzle yuav tsum tau muab tshem tawm thiab ntxuav los yog cov khoom txias qhov qhov thiab khiav seem ntawm cov pwm yuav tsum tau nthuav.

(6) Kev tsim tsis tsim nyog ntawm cov txheej txheem pouring.Thaum lub pwm muaj ntau qhov kab noj hniav, qhov zoo li qhov tsis xws luag ntawm cov khoom yas feem ntau tshwm sim los ntawm kev tsim tsis tsim nyog ntawm lub rooj vag thiab qhov sib npaug ntawm qhov sib npaug. Thaum tsim cov txheej txheem pouring, xyuam xim rau lub rooj vag sib npaug. Qhov hnyav ntawm cov khoom yas hauv txhua qhov kab noj hniav yuav tsum yog proportional rau lub rooj vag loj kom txhua qhov kab noj hniav tuaj yeem sau rau tib lub sijhawm. Lub rooj vag txoj hauj lwm yuav tsum tau xaiv ntawm phab ntsa tuab. Ib qho qauv tsim ntawm kev sib tw khiav sib npaug layout kuj tuaj yeem siv tau. Yog hais tias lub rooj vag los yog khiav yog me me, nyias, thiab ntev, lub siab ntawm cov khoom molten yuav ploj ntau dhau ntawm cov txheej txheem ntws, cov dej ntws yuav raug thaiv, thiab cov dej tsis zoo yuav tshwm sim. Hauv qhov no, qhov ntws channel hla ntu thiab lub rooj vag thaj tsam yuav tsum tau nthuav dav, thiab siv ntau txoj kev pub mis yog tias tsim nyog.

(7) Cov pwm tsis zoo.Thaum cov roj ntau ntxiv nyob rau hauv cov pwm vim cov pa tsis zoo yog nyem los ntawm cov khoom ntws, ua kom muaj kev kub siab ntau dua li qhov kev txhaj tshuaj, nws yuav tiv thaiv cov khoom molten los ntawm cov kab noj hniav thiab ua rau muaj kev txhaj tshuaj. Hauv qhov no, nws yuav tsum tau kuaj xyuas seb lub qhov dej txias puas tau teeb tsa lossis seb nws txoj haujlwm puas yog. Rau cov pwm nrog cov kab noj hniav sib sib zog nqus, cov grooves los yog cov qhov tso tawm yuav tsum tau ntxiv rau hauv qhov kev txhaj tshuaj; ntawm cov pwm saum npoo, lub qhov tso pa tawm nrog qhov tob ntawm 0.02 ~ 0.04 hli thiab qhov dav ntawm 5 ~ 10 hli tuaj yeem qhib tau, thiab lub qhov tso pa yuav tsum tau teem rau ntawm qhov kawg filling point ntawm kab noj hniav.

Thaum siv cov khoom siv raw nrog cov dej noo ntau dhau thiab cov ntsiab lus tsis hloov pauv, cov roj ntau kuj yuav raug tsim tawm, ua rau cov pwm tsis zoo. Nyob rau lub sijhawm no, cov khoom siv raw yuav tsum qhuav thiab volatiles yuav tsum tau muab tshem tawm.

Tsis tas li ntawd, nyob rau hauv cov nqe lus ntawm cov txheej txheem kev khiav hauj lwm ntawm lub pwm system, cov pa tsis zoo tuaj yeem txhim kho los ntawm kev ua kom pwm kub, txo qhov kev txhaj tshuaj ceev, txo qhov kev khiav hauj lwm ntawm cov txheej txheem pouring, txo cov clamping quab yuam, thiab ua kom cov pwm sib txawv.

(8) Cov pwm kub qis dhau lawm.Tom qab cov khoom molten nkag mus rau hauv qhov kub thiab txias pwm kab noj hniav, nws yuav tsis muaj peev xwm sau txhua lub ces kaum ntawm kab noj hniav vim txias ceev heev. Yog li ntawd, cov pwm yuav tsum tau preheated rau qhov kub thiab txias yuav tsum tau los ntawm cov txheej txheem ua ntej pib lub tshuab. Thaum lub tshuab nyuam qhuav pib, tus nqi ntawm cov dej txias dhau los ntawm cov pwm yuav tsum tau tswj kom tsim nyog. Yog tias cov pwm kub tsis tuaj yeem nce siab, qhov tsim ntawm pwm txias system yuav tsum tau kuaj xyuas seb puas tsim nyog.

(9) Lub melting kub yog tsawg heev.Feem ntau, nyob rau hauv ntau yam tsim nyog rau molding, cov khoom kub thiab qhov filling ntev yog ze rau ib tug zoo proportional kev sib raug zoo. Qhov kev ua tau zoo ntawm qhov kub qis qis qis qis, uas ua rau lub sijhawm ua kom ntev. Thaum cov khoom siv kub qis dua qhov ntsuas kub uas yuav tsum tau ua los ntawm cov txheej txheem, xyuas seb lub thoob ntim khoom puas zoo lawm thiab sim ua kom lub thoob kub.

Thaum lub tshuab nyuam qhuav pib, lub thoob kub ib txwm qis dua qhov ntsuas kub uas qhia los ntawm lub tshuab rhaub dej kub. Nws yuav tsum tau muab sau tseg tias tom qab lub chim yog rhuab mus rau lub ntsuas kub, nws tseem yuav tsum tau txias rau ib lub sij hawm ntawm lub sij hawm ua ntej lub tshuab yuav pib.

Yog tias qhov ntsuas kub qis yog qhov tsim nyog los tiv thaiv qhov decomposition ntawm cov khoom molten, lub sij hawm txhaj tshuaj yuav raug ncua kom tsim nyog kom kov yeej kev txhaj tshuaj. Rau cov ntsia hlau txhaj tshuaj molding tshuab, qhov ntsuas kub ntawm sab pem hauv ntej ntawm lub thoob tuaj yeem tsim nyog nce.

(10) Lub nozzle kub yog tsawg dhau.Thaum lub sij hawm txhaj tshuaj, lub nozzle yog nyob rau hauv kev sib cuag nrog pwm. Txij li cov pwm kub feem ntau qis dua qhov kub ntawm lub nozzle thiab qhov kub sib txawv yog qhov loj, kev sib cuag ntawm ob qho yuav ua rau lub nozzle kub poob, uas ua rau cov khoom molten khov ntawm lub nozzle.

Yog tias tsis muaj cov khoom txias hauv qhov pwm, cov khoom txias yuav khov tam sim tom qab nkag mus rau hauv cov kab noj hniav, kom cov kub yaj tom qab tsis tuaj yeem sau cov kab noj hniav. Yog li ntawd, lub nozzle yuav tsum tau muab cais tawm ntawm cov pwm thaum qhib pwm kom txo qhov cuam tshuam ntawm pwm kub ntawm lub nozzle kub thiab ua kom qhov kub ntawm lub nozzle nyob rau hauv ntau yam uas yuav tsum tau los ntawm tus txheej txheem.

Yog tias qhov kub ntawm lub nozzle qis heev thiab tsis tuaj yeem tsa tau, xyuas seb lub tshuab hluav taws xob nozzle puas puas thiab sim ua kom lub nozzle kub. Txwv tsis pub, lub siab poob ntawm cov khoom ntws loj dhau lawm thiab yuav ua rau qis qis.

(11) Kev txhaj tshuaj tsis txaus lossis tuav lub siab.Lub siab txhaj tshuaj yog ze rau qhov zoo proportional kev sib raug zoo nrog lub filling ntev. Yog tias qhov kev txhaj tshuaj me me dhau lawm, qhov ntev filling yog luv thiab cov kab noj hniav tsis puv puv. Hauv qhov no, qhov kev txhaj tshuaj siab tuaj yeem nce ntxiv los ntawm kev ua kom qeeb ntawm kev txhaj tshuaj rau pem hauv ntej thiab tsim nyog ncua sijhawm txhaj tshuaj.

Yog tias qhov kev txhaj tshuaj tsis tuaj yeem nce ntxiv, nws tuaj yeem kho tau los ntawm kev ua kom cov khoom siv kub, txo cov yaj viscosity, thiab txhim kho cov dej ntws ua haujlwm. Nws yog ib qho tsim nyog sau cia tias yog tias cov khoom kub siab dhau lawm, cov khoom siv molten yuav thermally decomposed, cuam tshuam rau kev ua haujlwm ntawm cov yas.

Tsis tas li ntawd, yog tias lub sijhawm tuav tau luv dhau, nws tseem yuav ua rau tsis txaus. Yog li ntawd, lub sij hawm tuav yuav tsum tau tswj nyob rau hauv ib qho kev tsim nyog, tab sis nws yuav tsum tau muab sau tseg tias ntev heev lub sij hawm tuav kuj yuav ua rau lwm yam txhaum. Thaum lub sij hawm molding, nws yuav tsum tau kho raws li qhov xwm txheej ntawm cov yas.

(12) Kev txhaj tshuaj nrawm dhau lawm.Qhov kev txhaj tshuaj nrawm yog ncaj qha ntsig txog qhov ntim ceev. Yog tias qhov kev txhaj tshuaj nrawm dhau lawm, cov khoom siv molten puv cov pwm maj mam, thiab cov khoom siv qis qis qis yog qhov yooj yim kom txias, uas ntxiv txo nws cov kev ua tau zoo thiab ua rau qis qis.

Hauv qhov no, kev txhaj tshuaj nrawm yuav tsum tau nce kom tsim nyog. Txawm li cas los xij, nws yuav tsum raug sau tseg tias yog tias qhov kev txhaj tshuaj nrawm dhau, nws yooj yim ua rau lwm yam molding tsis raug.

(13) Cov qauv tsim ntawm cov yas yog tsis tsim nyog.Thaum lub thickness ntawm cov yas tsis yog proportional rau qhov ntev, cov duab yog heev complex thiab molding cheeb tsam yog loj, cov khoom molten yog yooj yim thaiv nyob rau hauv lub nkag ntawm nyias-walled ib feem ntawm cov yas, ua rau nws nyuaj rau sau cov kab noj hniav. Yog li ntawd, thaum tsim cov qauv qauv ntawm cov yas, nws yuav tsum tau muab sau tseg tias lub thickness ntawm cov yas yog muaj feem xyuam rau qhov txwv txaus ntev ntawm cov khoom molten thaum lub sij hawm pwm filling.

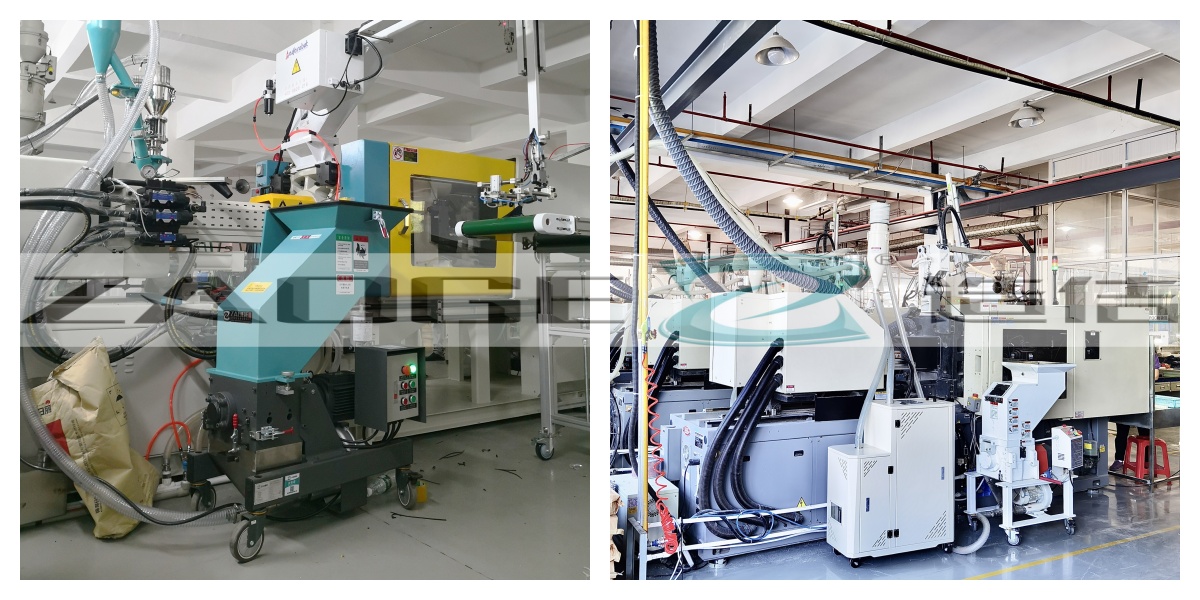

Yog li cas peb tuaj yeem yooj yim thiab zoo rov ua dua cov khoom siv khiav ua los ntawm kev txhaj tshuaj molding tshuab?ZAJ'spatented inline instant kub crushing thiab zoo instant recycling tov. To zoo dua tswj cov khoom zoothiabnqe. Covcrushed cov ntaub ntawv yog ib yam, huv si, tsis muaj plua plav, tsis muaj kuab paug, zoo siab, tov nrog raw cov ntaub ntawv los tsim cov khoom zoo.

Post lub sij hawm: Lub Xya hli ntuj-10-2024