1. Qhuav ntawm nylon PA66

Vacuum drying:kub ℃ 95-105 lub sij hawm 6-8 teev

Cua kub drying:kub ℃ 90-100 lub sij hawm txog 4 teev.

Crystallinity:Tsuas yog cov nylon pob tshab, feem ntau nylons yog crystalline polymers nrog siab crystallinity. Lub zog tensile, hnav tsis kam, hardness, lubricity thiab lwm yam khoom ntawm cov khoom raug txhim kho, thiab thermal expansion coefficient thiab dej nqus yuav txo qis, tab sis nws tsis zoo rau cov pob tshab thiab cuam tshuam. Pwm kub muaj qhov cuam tshuam zoo rau crystallization. Qhov kub ntawm pwm, qhov siab dua qhov crystallinity. Qhov qis pwm kub, qhov qis dua qhov crystallinity.

Shrinkage:Zoo ib yam li lwm cov khoom siv crystalline, nylon resin muaj teeb meem loj shrinkage. Feem ntau, qhov shrinkage ntawm nylon feem ntau cuam tshuam nrog crystallization. Thaum cov khoom muaj qib siab ntawm crystallinity, lub shrinkage ntawm cov khoom yuav kuj nce. Txo cov pwm kub, ua kom lub siab txhaj tshuaj, thiab txo cov khoom kub thaum lub sij hawm molding txheej txheem yuav txo qhov shrinkage, tab sis cov kev ntxhov siab sab hauv ntawm cov khoom yuav nce thiab nws yuav yooj yim rau deform. PA66 shrinkage yog 1.5-2%

Moulding khoom: Thaum molding nylon, xyuam xim rau kev tiv thaiv "casting phenomenon ntawm lub nozzle", yog li nws tus kheej-locking nozzles feem ntau yog siv rau kev ua cov ntaub ntawv nylon.

2. Cov khoom thiab pwm

- 1. Cov phab ntsa tuab ntawm cov khoom Cov dej ntws ntev piv ntawm nylon yog nyob nruab nrab ntawm 150-200. Cov phab ntsa tuab ntawm cov khoom nylon tsis tsawg dua 0.8mm thiab feem ntau xaiv ntawm 1-3.2mm. Tsis tas li ntawd, qhov shrinkage ntawm cov khoom muaj feem xyuam rau cov phab ntsa thickness ntawm cov khoom. Lub thickness ntawm phab ntsa, qhov ntau dua qhov shrinkage.

- 2. Exhaust tus nqi ntws ntawm nylon resin yog li ntawm 0.03mm, yog li lub qhov tso tawm qhov zawj yuav tsum tau tswj hauv qab 0.025.

- 3. Pwm kub: Pwm nrog nyias phab ntsa uas nyuaj rau pwm los yog xav tau crystallinity siab yog rhuab thiab tswj. Cov dej txias feem ntau yog siv los tswj qhov kub thiab txias yog tias cov khoom xav tau qee qhov kev hloov pauv.

3. Nylon molding txheej txheem

Barrel kub

Vim hais tias nylon yog crystalline polymer, nws muaj qhov tseem ceeb melting point. Lub chim kub xaiv rau nylon resin thaum txhaj tshuaj molding muaj feem xyuam rau kev ua tau zoo ntawm cov resin nws tus kheej, cov khoom siv, thiab cov duab ntawm cov khoom. Nylon 66 yog 260 ° C. Vim qhov tsis zoo thermal stability ntawm nylon, nws tsis tsim nyog nyob hauv lub thoob ntawm qhov kub thiab txias rau lub sijhawm ntev kom tsis txhob muaj xim daj thiab daj ntawm cov khoom. Nyob rau tib lub sijhawm, vim qhov zoo fluidity ntawm nylon, nws ntws sai sai tom qab qhov kub thiab txias tshaj nws cov ntsiab lus melting.

Txhaj tshuaj

Lub viscosity ntawm nylon yaj yog tsawg thiab fluidity yog zoo, tab sis lub condensation ceev yog ceev. Nws yog ib qho yooj yim kom muaj teeb meem tsis txaus ntawm cov khoom nrog cov duab thiab cov phab ntsa nyias, yog li tseem yuav tsum tau txhaj tshuaj ntau dua.

Feem ntau, yog tias lub siab siab dhau lawm, cov khoom yuav muaj teeb meem overflow; Yog tias qhov siab qis dhau lawm, cov khoom yuav muaj qhov tsis xws luag xws li ripples, npuas, pom tseeb sintering cov cim lossis cov khoom tsis txaus. Kev txhaj tshuaj siab ntawm cov nylon feem ntau tsis tshaj 120MPA. Feem ntau, nws raug xaiv nyob rau hauv thaj tsam ntawm 60-100MPA kom tau raws li qhov yuav tsum tau muaj ntawm cov khoom siv feem ntau. Tsuav yog cov khoom tsis muaj qhov tsis xws luag xws li npuas thiab dents, nws yog feem ntau tsis tsim nyog siv lub zog tuav ntau dua kom tsis txhob muaj kev ntxhov siab sab hauv ntawm cov khoom. Kev txhaj tshuaj nrawm Rau nylon, qhov kev txhaj tshuaj nrawm nrawm dua, uas tuaj yeem tiv thaiv ripples thiab tsis txaus pwm txhaws los ntawm kev ua kom txias ceev heev. Kev txhaj tshuaj nrawm nrawm tsis muaj qhov cuam tshuam loj rau kev ua haujlwm ntawm cov khoom.

Pwm kub

Pwm kub muaj qee yam cuam tshuam rau crystallinity thiab molding shrinkage. Cov pwm kub kub muaj crystallinity siab, nce hnav tsis kam, hardness, elastic modulus, txo dej nqus, thiab nce molding shrinkage ntawm cov khoom; pwm kub tsis tshua muaj crystallinity, zoo toughness, thiab siab elongation.

Txhaj tshuaj molding rhiav tsim sprues thiab cov neeg khiav dej num txhua hnub, yog li cas peb tuaj yeem yooj yim thiab siv tau zoo dua cov sprues thiab cov neeg khiav dej num uas tsim los ntawm kev txhaj tshuaj molding tshuab?

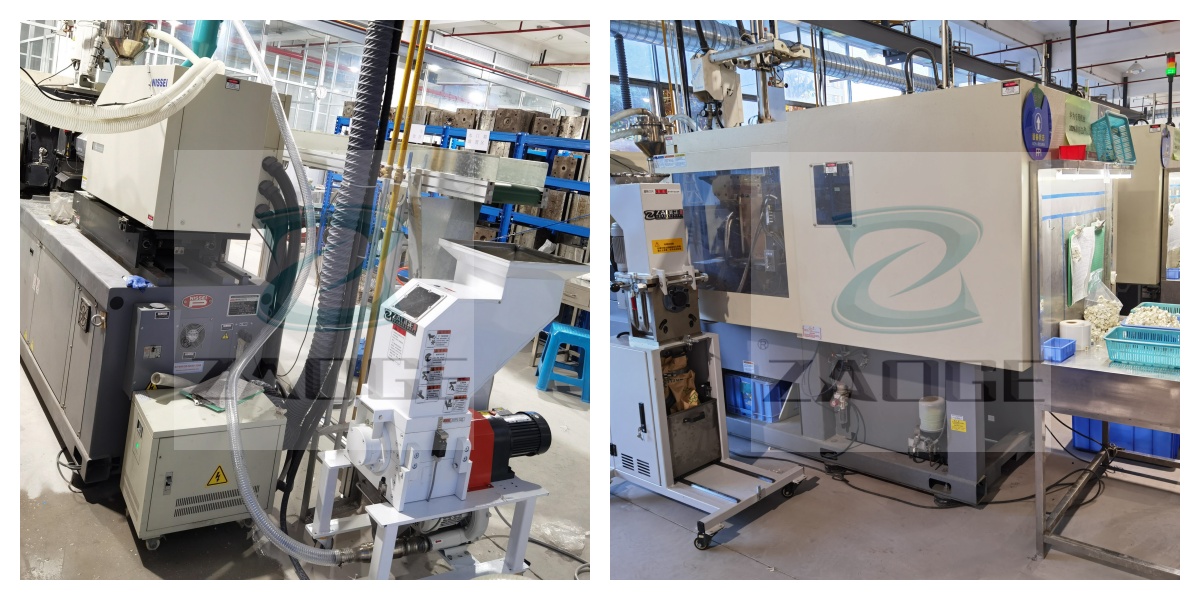

Cia nws musZAOGE ib puag ncig kev tiv thaiv thiab cov khoom siv-txuag kev txhawb nqa (yas crusher)rau kev txhaj tshuaj molding tshuab.

Nws yog lub sijhawm tiag tiag kub sib tsoo thiab rov ua dua tshiab uas tau tsim tshwj xeeb los tsoo cov khoom kub kub thiab cov neeg khiav dej num.

Ntxuav thiab qhuav crushed hais tam sim ntawd rov qab mus rau cov kab ntau lawm kom tam sim ntawd tsim Txhaj molded qhov chaw.

Ntxuav thiab qhuav cruhsed hais yog hloov mus rau cov ntaub ntawv zoo raw khoom siv es tsis txhob downgrading.

Nws txuag cov khoom siv raw thiab nyiaj txiag thiab tso cai rau kev tswj tus nqi zoo dua.

screenless qeeb ceev ganulator

Post lub sij hawm: Lub Xya hli ntuj-24-2024