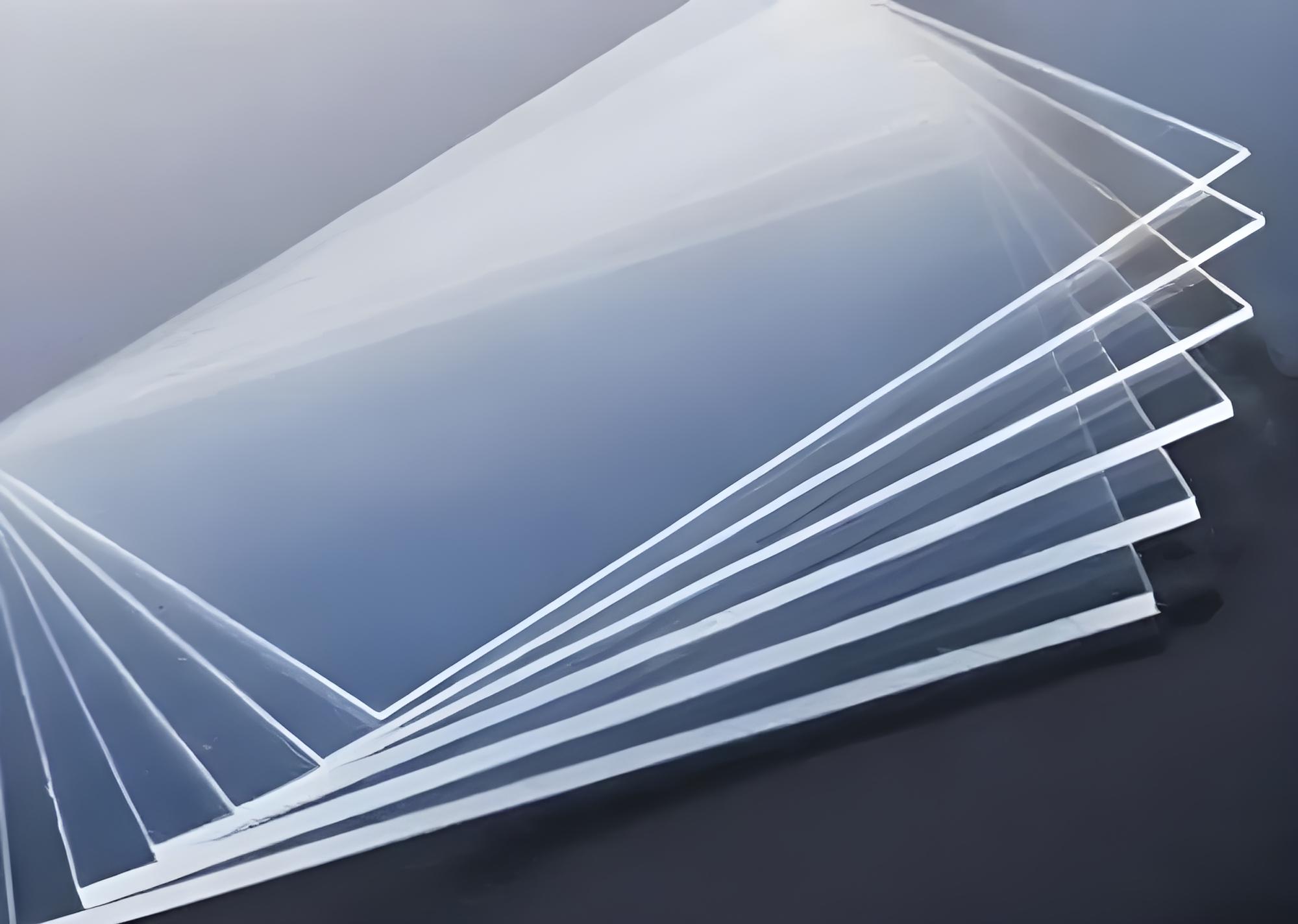

Lub npe tshuaj ntawm acrylic yog polymethylmethacrylate (PMMA hauv lus Askiv). Vim tias qhov tsis zoo ntawm PMMA xws li qhov tsis zoo ntawm qhov tawv tawv, yooj yim rubbing, tsis tshua muaj kev cuam tshuam, thiab kev ua haujlwm tsis zoo ntawm cov pwm pwm, kev hloov kho ntawm PMMA tau tshwm sim ib zaug. Xws li copolymerization ntawm methyl methacrylate nrog styrene thiab butadiene, kev sib xyaw ntawm PMMA thiab PC, thiab lwm yam.

Kev coj tus cwj pwm ntawmPMMAyog qhov phem dua li ntawm PS thiab ABS, thiab cov viscosity yaj yog rhiab rau qhov kub thiab txias. Thaum lub sij hawm molding txheej txheem, cov yaj viscosity feem ntau hloov raws li qhov kub thiab txias. PMMA yog ib qho amorphous polymer nrog melting kub siab tshaj 160°C thiab decomposition kub ntawm 270°C.

1. Kev pov tseg ntawm cov yas

PMMA muaj qee qhov kev nqus dej, nrog rau qhov nqus dej ntawm 0.3-0.4%. Kev txhaj tshuaj molding yuav tsum muaj cov av qis dua 0.1%, feem ntau yog 0.04%. Lub xub ntiag ntawm noo noo ua rau npuas, huab cua streaks, thiab txo cov pob tshab hauv cov yaj. Yog li nws yuav tsum tau qhuav. Qhov kub kom qhuav yog 80-90℃thiab lub sij hawm ziab yog ntau tshaj 3 teev. Cov khoom siv rov ua dua tuaj yeem siv tau 100% hauv qee kis. Tus nqi tiag tiag nyob ntawm qhov yuav tsum tau ua, feem ntau ntau dua 30%. Cov khoom siv rov qab yuav tsum raug zam los ntawm kev sib kis, txwv tsis pub nws yuav cuam tshuam rau cov pob tshab thiab cov khoom ntawm cov khoom tiav.

2. Kev xaiv ntawm kev txhaj tshuaj molding tshuab

PMMA tsis muaj cov cai tshwj xeeb rau kev txhaj tshuaj molding tshuab. Vim nws lub siab yaj viscosity, nws yuav tsum tau ib tug ntxaum zawj thiab ib tug loj txoj kab uas hla nozzle qhov. Yog hais tias lub zog yuav tsum tau ntawm cov khoom yog siab dua, ib tug ntsia hlau nrog ib tug loj nam piv yuav tsum tau siv rau low-temperature plasticization. Tsis tas li ntawd, PMMA yuav tsum tau muab khaws cia rau hauv lub hopper qhuav.

3. Pwm thiab rooj vag tsim

Cov pwm kub tuaj yeem yog 60℃-80℃. Txoj kab uas hla ntawm lub ntsiab channel yuav tsum phim lub puab taper. Qhov zoo tshaj plaws lub kaum sab xis yog 5° rau 7°. Yog tias koj xav txhaj pwm 4 hli lossis siab dua cov khoom, lub kaum sab xis yuav tsum yog 7° thiab txoj kab uas hla ntawm lub ntsiab channel yuav tsum yog 8 mus rau 8°. 10mm, tag nrho ntev ntawm lub rooj vag yuav tsum tsis txhob ntau tshaj 50mm. Rau cov khoom uas muaj phab ntsa thickness tsawg dua 4 hli, qhov ntws channel txoj kab uas hla yuav tsum yog 6-8 hli

Rau cov khoom uas muaj phab ntsa thickness ntau dua 4 hli, txoj kab uas hla ntawm tus khiav yuav tsum yog 8-12 hli. Qhov tob ntawm kab pheeb ces kaum, kiv cua-zoo li tus thiab ntsug hlais rooj vag yuav tsum yog 0.7 mus rau 0.9t (t yog phab ntsa thickness ntawm cov khoom). Txoj kab uas hla ntawm rab koob rooj vag yuav tsum yog 0.8 mus rau 2 hli; qhov me me yuav tsum tau xaiv rau cov viscosity tsawg.

Cov qhov cua feem ntau yog nyob rau hauv 0.05 tob, 6 hli dav, thiab lub kaum sab xis yog nruab nrab ntawm 30'-1° thiab kab noj hniav yog nruab nrab ntawm 35'-1°30°.

4. Melt kub

Nws tuaj yeem ntsuas los ntawm txoj kev txhaj tshuaj hauv huab cua: txij li 210℃rau 270℃, nyob ntawm cov ntaub ntawv muab los ntawm tus neeg muag khoom.

Tawm ntawm lub rooj zaum rov qab, ua rau lub tshuab txhaj tshuaj molding nozzle tawm ntawm lub ntsiab channel bushing, thiab tom qab ntawd manually ua cov yas txhaj tshuaj molding, uas yog cua txhaj tshuaj molding.

5. Kev txhaj tshuaj kub

Kev txhaj tshuaj nrawm tuaj yeem siv tau, tab sis kom tsis txhob muaj kev ntxhov siab sab hauv, nws yog qhov zoo dua los siv ntau theem kev txhaj tshuaj, xws li qeeb-ceev-slow, thiab lwm yam. Thaum txhaj cov tuab tuab, siv qeeb ceev.

6. Lub sijhawm nyob

Yog tias qhov kub thiab txias yog 260°C, lub sijhawm nyob tsis tuaj yeem tshaj 10 feeb. Yog tias qhov kub thiab txias yog 270°C, lub sijhawm nyob tsis tuaj yeem tshaj 8 feeb.

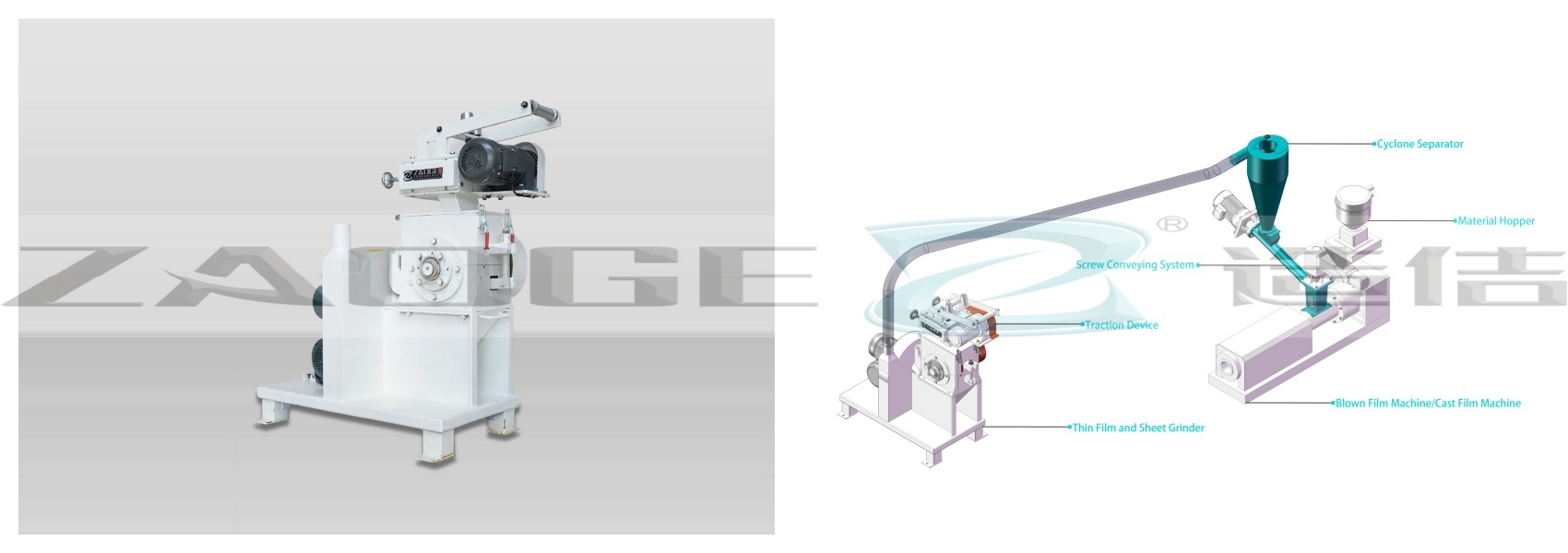

ZAOGE Zaj duab xis Crusheryog tsim rau crushing ntau yam mos thiab tawv ntug cov ntaub ntawv nrog ib tug tuab ntawm 0.02 ~ 5MM, xws li PP / PE / PVC / PS / GPPS / PMMA films, nplooj ntawv, thiab daim hlau siv nyob rau hauv ntawv sau, ntim, thiab lwm yam lag luam.

Nws tuaj yeem siv los sau, tsoo thiab xa cov khoom seem uas tsim los ntawm extruders, laminators, ntawv tshuab, thiab phaj tshuab. Piv txwv li, cov ntaub ntawv crushed yog thauj los ntawm ib tug conveying kiv cua los ntawm ib tug pipeline mus rau lub cyclone separator, thiab ces thawb mus rau hauv lub extruder ntsia hlau feed chaw nres nkoj los ntawm ib tug noj cov ntsia hlau rau tsis siv neeg sib tov nrog cov ntaub ntawv tshiab, yog li ua tiav instant kev tiv thaiv ib puag ncig thiab siv.

Lub sij hawm xa tuaj: Plaub Hlis-01-2024